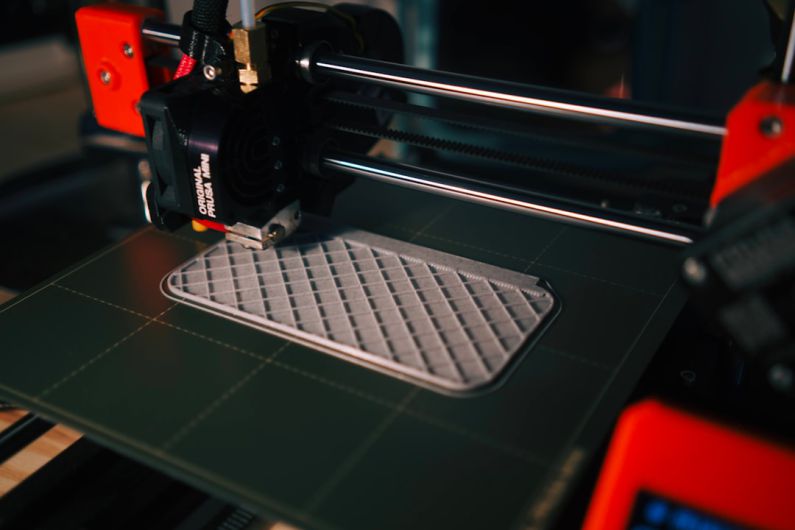

3D printing technology has revolutionized various industries, including cooling technologies, by offering innovative solutions and advancements. The versatile nature of 3D printing allows for the creation of complex designs with precision and speed, making it an ideal tool for enhancing cooling systems in various applications. From aerospace to electronics, the utilization of 3D printing techniques in cooling technologies has opened up new possibilities for more efficient and effective cooling solutions.

Innovative Cooling Designs

One of the key advantages of using 3D printing techniques in cooling technologies is the ability to create intricate and customized designs that are tailored to specific cooling requirements. Traditional manufacturing methods often have limitations in producing complex geometries, but 3D printing allows for the fabrication of intricate structures that can optimize heat dissipation. By leveraging 3D printing technology, engineers can design cooling solutions that are not only more efficient but also more compact and lightweight, making them ideal for applications where space is limited.

Enhanced Heat Transfer

Efficient heat transfer is crucial for the performance and longevity of electronic devices, and 3D printing techniques have been instrumental in improving heat dissipation in various cooling systems. By utilizing advanced materials and design capabilities offered by 3D printing, engineers can create cooling components with enhanced thermal conductivity and heat dissipation properties. This results in more effective cooling solutions that can effectively manage heat generation in electronic devices, ensuring optimal performance and reliability.

Optimized Fluid Dynamics

Fluid dynamics play a vital role in cooling technologies, and 3D printing techniques have enabled the creation of cooling components that are optimized for fluid flow and heat transfer. By designing intricate structures and channels within cooling systems, engineers can manipulate fluid dynamics to achieve better heat dissipation and thermal management. The ability to customize cooling components using 3D printing allows for the creation of innovative designs that can maximize the efficiency of cooling systems in various applications.

Rapid Prototyping and Iterative Design

3D printing technology has revolutionized the prototyping process in cooling technologies by enabling rapid prototyping and iterative design cycles. Engineers can quickly produce prototypes of cooling components and test them in real-world conditions, allowing for faster design iterations and optimization of cooling solutions. This accelerated prototyping process not only speeds up the development timeline but also enables engineers to fine-tune cooling designs to achieve optimal performance and efficiency.

Cost-Effective Manufacturing

In addition to its design capabilities, 3D printing offers cost-effective manufacturing solutions for cooling technologies. Traditional manufacturing methods often involve high setup costs and long lead times, making them less suitable for low-volume production runs or customized cooling solutions. 3D printing allows for on-demand production of cooling components without the need for expensive tooling or molds, making it a cost-effective solution for producing small batches of custom cooling systems. This flexibility in manufacturing not only reduces production costs but also enables the creation of bespoke cooling solutions tailored to specific requirements.

Future Implications and Advancements

The integration of 3D printing techniques in cooling technologies holds immense potential for future advancements in thermal management and heat dissipation. As 3D printing technology continues to evolve, we can expect to see further innovations in cooling system design, materials, and manufacturing processes. From advanced cooling solutions for next-generation electronics to sustainable cooling technologies for renewable energy systems, the possibilities are endless with the application of 3D printing techniques in cooling technologies.

Embracing the Future of Cooling Technologies

In conclusion, the application of 3D printing techniques in cooling technologies has ushered in a new era of innovation and efficiency in thermal management. By leveraging the design capabilities, enhanced heat transfer properties, and cost-effective manufacturing solutions offered by 3D printing, engineers can create cutting-edge cooling systems that are tailored to specific requirements and optimized for performance. As we continue to explore the potential of 3D printing in cooling technologies, we can expect to see further advancements that will shape the future of thermal management across various industries.